Description

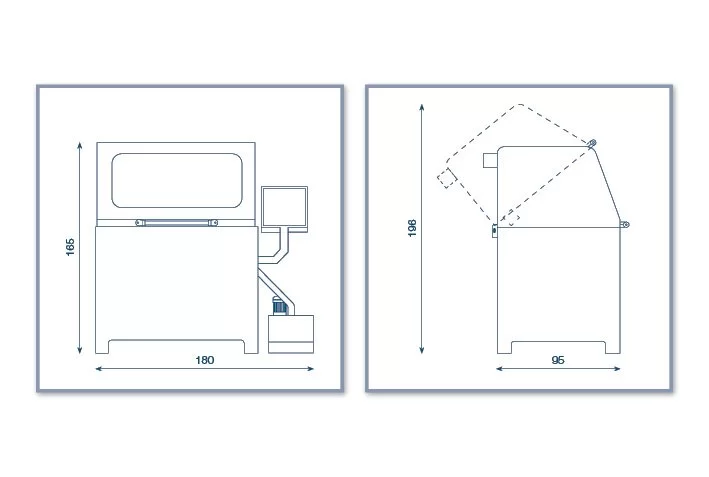

Technical Data

| Maximum circular knife diameter | 500 mm |

| Bevel angle | da +70° a -10° |

| Grinding wheel spindle slide stroke | 150 mm |

| Grinding wheels diameter | 150 mm |

| Grinding wheels bore size | 20 mm |

| Grinding wheels speed | 4250 rpm |

| Grinding wheel motor power | 1,5 kW |

| Installed power | 4 kVA |

| Weight | 750 kg |

Features

- PLC controlled grinding machine

- Cabin for full working area enclosure

- Grinding with emulsion coolant or neat oil

- Control board equipped with panel PC with 10” (16:9) touch screen display, and USB port for connection of mouse, keyboard, Wi-Fi adapter, flash drive

- Easy adjustment for bevel angle

- Quick assembly of circular knife

- Joystick for manual displacement of the grinding slide, with potentiometer for speed adjustment

- Ball rail guide of slides for increased accuracy and durability

- Circular knife spindle with rotation speed digitally programmed and controlled

- Centralized lubrication with manual pump

- LED tube lamp for grinding area lighting, degree of protection IP67

- Interchangeable shaft, to accommodate a suitable knife clamping system

- Versatility, efficiency, and easy to operate

- Low and simple maintenance

Standart Software

- Windows® operative system, with graphic operator interface, menu guidance, machine diagnostic, historical data

Operator interface in English language - Saving of 5000 working programs, and ability to export the saved working programs in a USB device, and to import working programs from a USB device

- Working cycle for the grinding of unilateral or bilateral bevel knives, and bottom knives, with programming of total stock removal, roughing and finishing in-feeds, sparking out cycle, rotation speeds of the circular knife

- All machine functions (start/stop motors, knife rotation speeds, alarms, etc.) are controlled by the PLC and the panel PC with touch screen display

- Automatic cycle repetition, with automatic fast engagement, circular knife/ grinding wheel, and automatic starts of all motors, for grinding batches of unilateral bevel circular knives at a same diameter, bilateral bevel knives with the cutting edge centered with the knife body and at a same diameter if necessary, bottom knives at a same thickness

- Rotation speed of the circular knife digitally programmable from 5 to 40 rpm for the removal cycle, and from 3 to 55 rpm for the sparking out cycle, and digitally controlled

- Digital continuous control of grinding wheel spindle motor load current, with interactive ammeter, and selection of intervention if the maximum load current threshold is reached

- Programming of a new working cycle during the automatic cycle

- Indication of the time remaining to the end of the automatic cycle, and the total time of the automatic cycle

- Automatic shutdown of all motors on completion of automatic cycle

Optional Equipment

- Various types of high pressure coolant facilities and filtering systems

- Various types of mist extraction units

- Automatic centralized lubrication

- Machine status control lamp