Description

STAHLTEK PREDATOR

TCT CERMET circular saw blades, with cermet teeth, not coated, used for low or mild carbon steel cutting, solid material or thick-walled pipes, on stationary machines like Amada, Nishijima, Tsune, Kasto, Everising. Not to be used to cut stainless steel.

STAHLTEK APACHE

TCT HM P.V.D. Coated circular saw blade, with tungsten carbide teeth, pvd coated, used for mild or high carbon or stainless steel cutting, solid material or thick-walled pipes, on stationary machines like Amada, Nishijima, Tsune, Kasto, Everising. Suitable for high demanding applications.

TUBOTEK PHANTOM

TCT HM P.V.D. Coated circular saw blade, used for cutting tubes with wall thickness greater than 3 mm, in medium or high carbon steel, and stainless steel, on automatic sawing machines. A higher cutting speed can be achieved than with HSS saw blades. Tubotek Phanton guarantees high performance cutting of thin walled tubes, obtaining perfect surface and burr free pipes.

FLYTEK RAPTOR

TCT HM P.V.D. Coated circular saw blade used for cutting steel tubes with wall thickness greater than 3 mm, on flying cutting machines (single or twin). The special geometry reduces vibration during the cutting process and helps the chip evacuation.

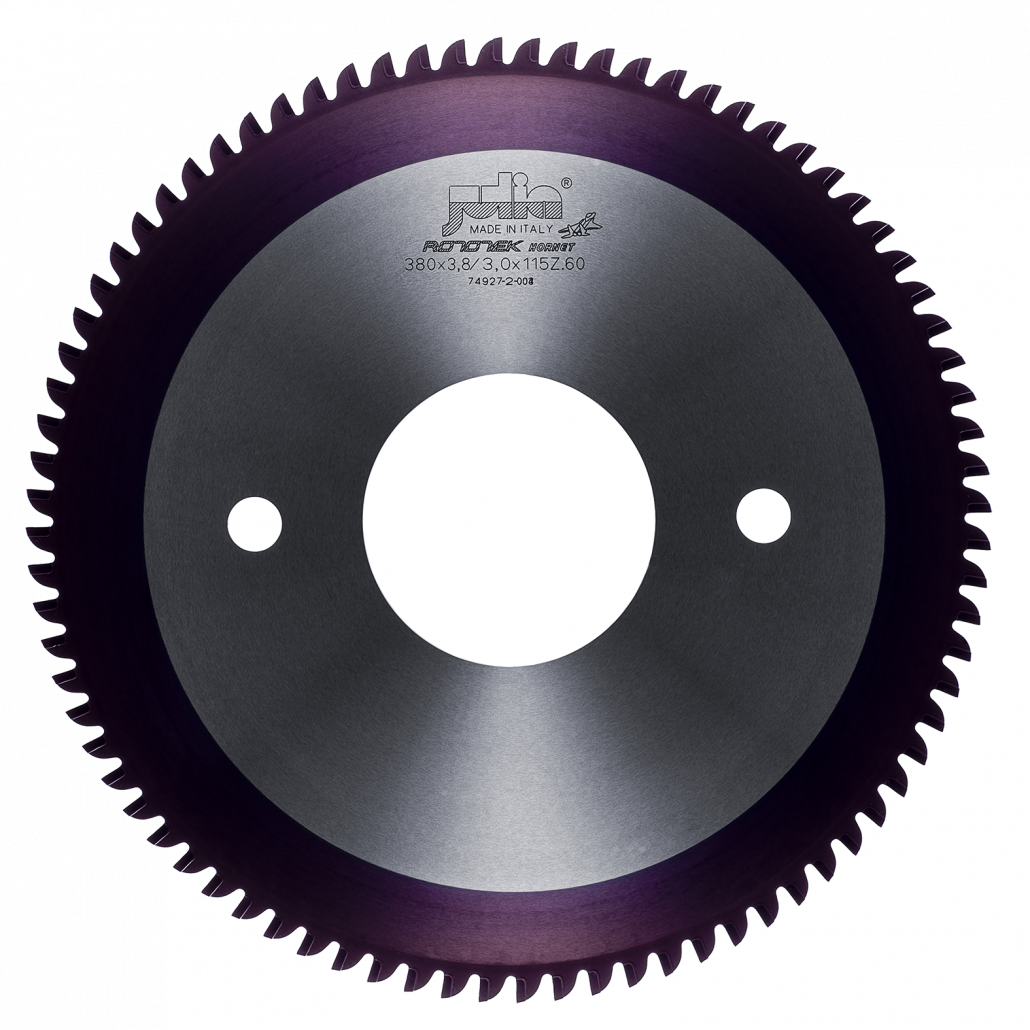

ROTOTEK HORNET

TCT HM P.V.D. Coated Re-sharpenable circular saw blade used for cutting tubes with wall thickness greater than 3 mm. These saw blades have been designed for orbital flying cut-off applications on tube mills. Key features of these products are fracture resistant carbide tips and low vibration during the cutting process. The result is a very long blade life when used on machines such as: Kusakabe, Linsinger, Mair, Nakata, Oto Mills, Sms-Meer.

OINTEK INTRUDER

TCT HM P.V.D. Coated circular saw blade. One of the industry challenges is to remove welding residue inside pipes, which drastically compromises the cutting, and thus the blade life. This problem decreases the life of the circular saw blade by damaging the carbide tip, especially on standard TCT saw blades.

Due to its special design and reinforced tooth form, Jointek Intruder has a very specific tooth geometry in order for it to withstand heavy duty cutting cycles with violent bumps, on continuous welded pipes.