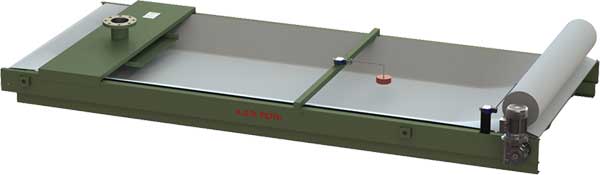

Description

FEATURES

- continuous, automatic operation

- filtration degree between 15 and 50 microns depending on filtering fabric used

- C-X- and CL-X versions available made entirely of stainless steel

- overlapped bed versions available for high flow rates and to save space

MACHINING

• LAPPING – PROFILING AND DRAWING – ROLLING

• MACHINING CENTRES – WASHING MACHINES – TURNING – INDUSTRIAL SAWS

• FOOD – PLASTIC – RECYCLING

TECHNICAL DATA

The liquid that needs filtering is introduced into the diffuser and evenly distributed on the filtering fabric which allows the filtered liquid to drain, capturing any polluting particles. These gradually build up on the filtering fabric forming a sponge-like layer which also acts as a filter, until it becomes clogged. At this point, the liquid can longer pass through the filtering fabric. The liquid level rises until it activates the relevant sensor which controls the conveyor belt feed and the subsequent replacement of the exhausted filtering fabric with new fabric.

The exhausted filtering fabric full of sludge is removed from the filter into a bin and new filtering fabric is introduced replacing it. To make the most of the filtering power of the layer of sludge deposit, only a few centimetres of filtering fabric are replaced.

The filtered liquid drains into a collection tank and is then recycled by an electric pump.

The filtration process is completely automated. The operator must check the input of the clean filtering fabric. To further simplify the operation, a mechanical sensor which detects the “end of roll” is available on request.