Description

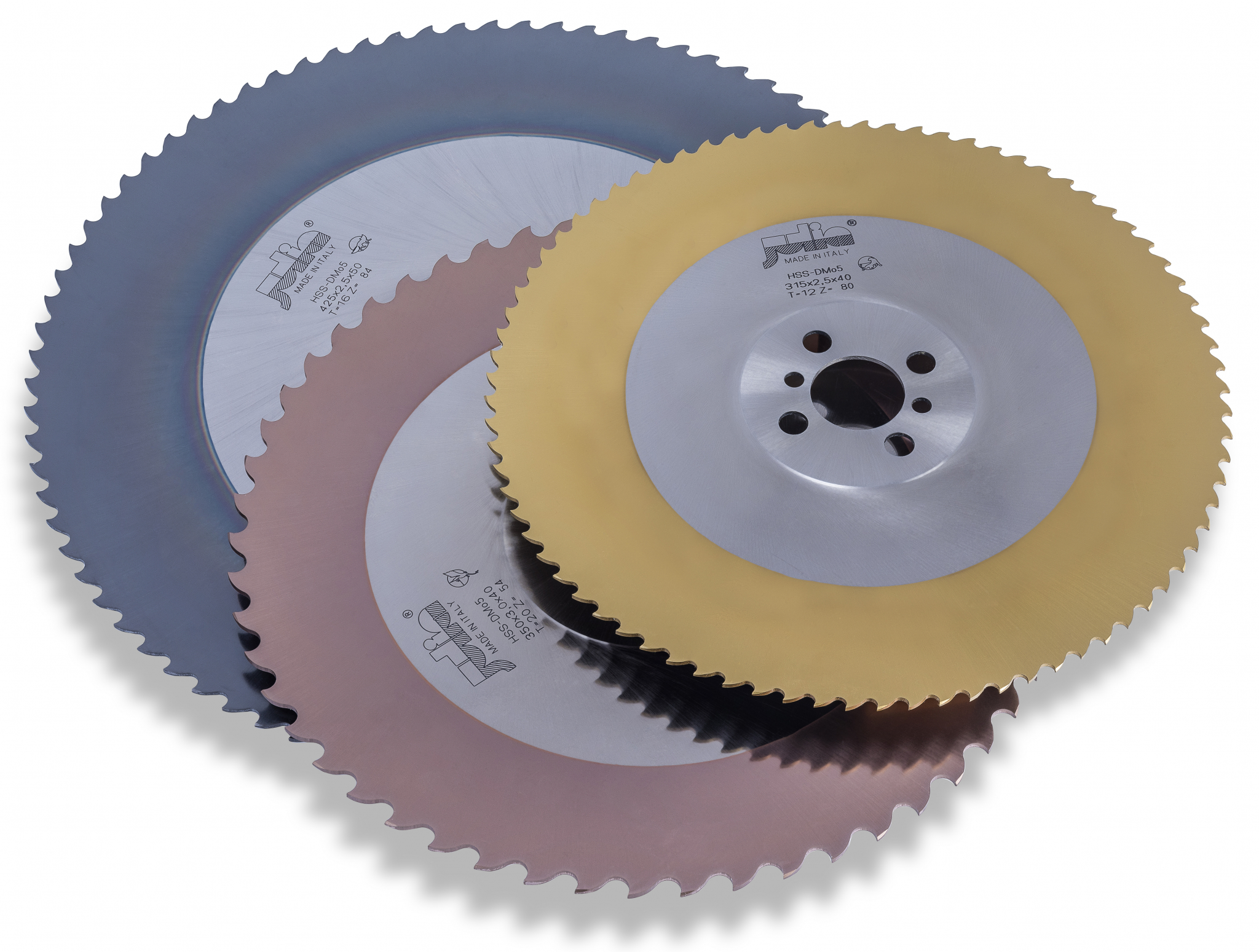

HSS – Co5 Cut Off Saws

This is our standard product used for cutting stainless steel and medium hard steel 550 – 700 MPa. It is a super high-speed steel that contains all the alloy elements already present in the Dmo5, plus 5% cobalt.

The cobalt does not form carbides, but ensures stability, preventing critical grain enlargement, and above all maintains extreme hardness during working temperatures. This peculiarity is very important when cutting very adherent materials such as stainless steel and very hard metals with high cutting temperatures.

The production range is the same as the Hss-Dmo5 products.

Evolution

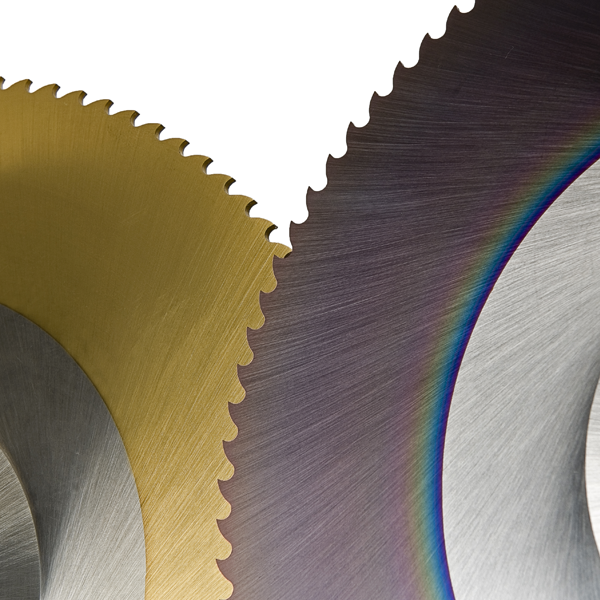

This is a new product developed by our R&S department together with the mechanical division of the Trento’s university. Our goal was to find a special saw blade to improve the cutting speed when working with steel pipes and solid bars with hardness 650 – 850 MPa, when using high performance cut off machines.

This product is recommended to cut carbon steel and stainless steel. The most important characteristics of the EVOLUTION circular saw blades are:

- Special HSS steel with high wear resistance and extra fine grain

- Multilayer PVD coating with a surface hardness higher than 3400 HV.

- Special production process with very tight manufacturing tolerances

- Side run out and flatness are very low

EVOLUTION is manufactured with the best coating ever developed by Julia’s R&S department. This is a coating with a special composition, achieved by following a precise and specific recipe of noble elements, which achieves the highest surface hardness amongst traditional coatings, and offers great heatsinking capacity.

Ultra

The top of Julia’s range of HSS saw blades, offering the high tenacity of steel and the performance of carbide.

This circular saw blade is normally used by our customers who cut hard steel > 1250 MPa.

Using this very special product, it is usually possible to achieve better results than with TCT carbide saw blades. Julia recommends ULTRA to cut very hard steel in the automotive industry, for stainless steel, titanium etc.

The most important features of this product are:

- Special HSS steel saw blade with hardness above 950 HV and extra fine grain

- Innovative multilayer PVD coating with a surface hardness higher than 3650 HV.

- Production process with very tight manufacturing tolerances

- Teeth with a specific profile for high performance cuts

- Restricted “side-runout” tolerances always apply with Ultra.

The result: Hardness, tenacity, finish and durability – all you need for an excellent cut.

ULTRA is provided with the best coating ever developed by Julia’s R&S department.

This is a coating with a special composition, achieved by following a precise and specific recipe of noble elements, which achieves the highest surface hardness amongst traditional coatings and offers great heatsinking capacity.

Thanks to its very limited side-runout, restricted cutting tolerances are always respected, even on the toughest materials and in difficult conditions. This combination makes the Ultra the top performing blade on the market.