Description

Features

- Cabin for full working area enclosure

- Control board equipped with panel PC with 10” (16:9) touch screen display, and USB port connection of mouse and Wi-Fi adapter

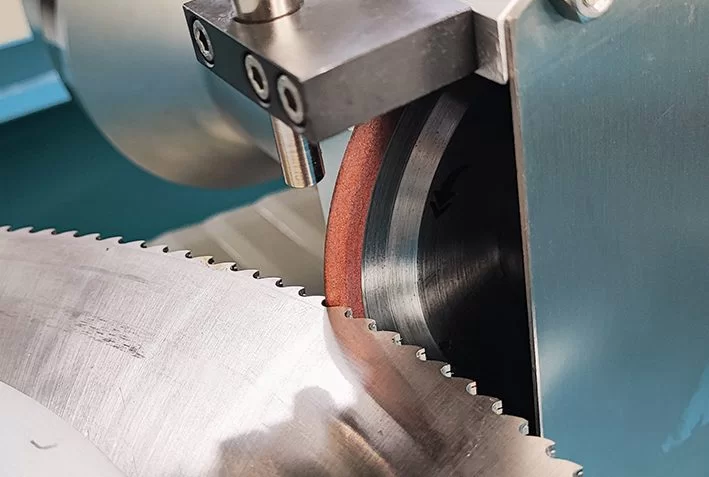

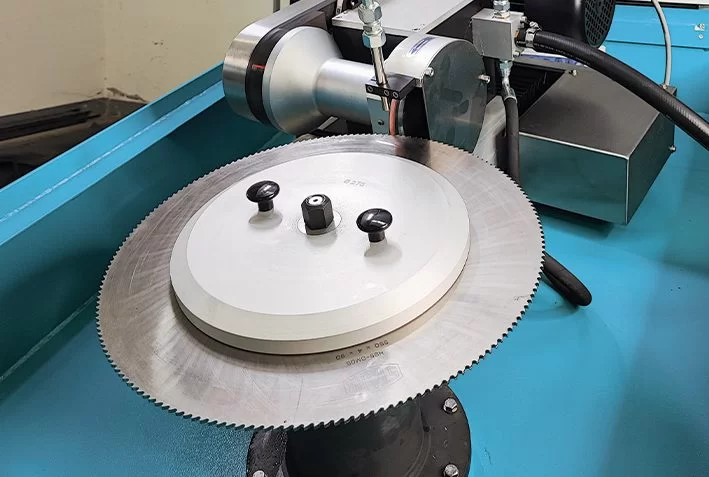

- Sharpening, re-toothing, and chamfering of metalcutting circular saw blades

- High pressure coolant facility withfiltering system

- Mist extraction unit

- Electronic handwheel for manual displacement of grinding slide

- High rigidity and accurate assembly of the circular saw blade with clamping flanges

- Quick adjustment for chamfering

- Automatic centralized lubrication with programmable electropump

- LED tube lamp for working area lighting, protection grade IP67

Standart Software

- Windows operative system, with graphic operator interface, menu guidance, machine diagnostic.

Operator interface in English language - Sharpening and making new teeth forms A, AW, B, BW, C according to DIN 1840

- Tooth rake and clearance angles, freely and individually programmable

- Free programming of the tooth depth ±20% of the value calculated by CNC

- Chamfering of the tooth

- Compensation for the grinding wheel thickness

- Saving of 99 entire working cycles

- Indication of working cycle time remaining

Optional Software

- Sharpening and making new teeth of friction circular saw blades

- Sharpening and making new teeth of HSS circular saw blade with variable tooth pitch, with free programming of pitch variation

- Sharpening and making new teeth of matched circular saw blades on a same diameter

- Sharpening and making new teeth of solid carbide circular saw blades

- Cylindrical grinding for grinding down all teeth on circular saw blades with broken teeth, with programmable and fully automatic working cycle

- Grinding of radial slots and scallops on circular knives and circular blades

- Tooth geometry modification with storage of the customized tooth forms

- Sharpening and making new teeth with special tooth form

Optional Equipment

- Machine version for grinding HSS circular saw blades from 150 to 650 mm diameter, and friction circular saw blades form 150 to 710mm diameter

- Clamping fixture for circular saw blades form 50 to 150 mm diameter

- Various type of high pressure coolant facilities and filtering systems

- Various tupe of mist extraction units

- Ammeter for indicattion of the load current of the grinding wheel motor

- Control lamp for indication “End Automatic Cycle”