Description

MACHINING

• LAPPING – PROFILING AND DRAWING – ROLLING

• MACHINING CENTRES – WASHING MACHINES – TURNING – INDUSTRIAL SAWS

• FOOD – PLASTIC – RECYCLING

TECHNICAL DATA

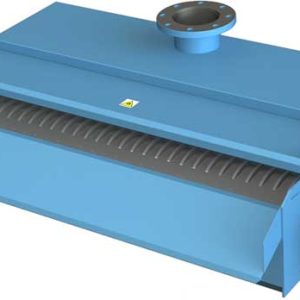

The filtration process is completely automatic. The liquid that needs filtering is introduced into the filtration system through the diffuser where it is pre-filtered before being fed into the tank with a dredge conveyor and then, filtered through a micro-mesh.

The liquid drains through the micro-mesh wrapped around the drum which then starts to fill up with filtered liquid. The liquid flows out from the inside of the drum by force of gravity or is extracted by a suction pump. Shaped parts on the sides of the rotating drum ensure that the micro-mesh adheres perfectly to the drum so that only the filtered liquid passes through it.

The pollutant, meanwhile, settles on the micro-mesh forming a spongy layer which, in turn, contributes to the filtration process. When this layer becomes too thick and dense, the liquid can no longer pass through the clogged micro-mesh, so the liquid rises until it reaches the maximum level. At this point, the level sensor (mechanical or electronic) installed on the filter sends a starter signal to the drum rotation motor. The clogged micro-mesh is then washed from both the inside and outside via two nozzle bars fed with clean liquid taken from inside the drum. To make the most of the filtering power of the layer of accumulated sludge, only a few centimetres of micro-mesh are cleaned.